| FAQContact UsLive Chat tel. 1-866.473.6900 |

TORBAL ® Rx brings you pillcounting.com - experience our tablet counters, learn about our technology, understand the features...

Pill counting on the DRX five-S is easy: Once the scale is turned on, it will automatically calibrate itself and enter the pill counting mode. The scale will then indicate you should place a vial on the pan and tare it by pressing one of the dual tare keys. Once the vial is tared, the scale will indicate you should scan the NDC barcode found on the drug’s supply bottle. Using our high performance laser scanner, simply scan the barcode. If the drug has been previously entered into the database, the drug’s NDC number as well as the name and lot number will be displayed, and the scale will indicate you should begin filling. Tablets are filled and counted essentially as quickly as they are poured into the vial.

Perhaps one of the scale’s most valuable features is its ability to verify that the correct drug is counted and filled. When enabled, verification becomes part of the pill counting process. The steps are very easy to follow: first as always, tare the vial. The scale will then indicate you should perform “scan one,” which is scanning the NDC barcode located on the drug’s supply bottle. After you scan the supply bottle, the scale will indicate you should perform “scan two.” You must then scan the NDC barcode located on the prescription label. After the second scan is performed, the scale checks to see if the codes are the same. If no discrepancy is found, “Match OK” is displayed and you are allowed to continue with pill counting. However, if the NDC barcodes differ, the display shows “Failed” and you will not be allowed to continue. You can also verify prescription drugs that do not require pill counting such as creams and inhalers.

The easiest way to keep a log or paper trail of pill counts is to use our RXP 4 Thermal Printer. After performing a count, simply press the Data Transfer key to print. The printer will produce a receipt that indicates the date and time of the performed transaction as well as the NDC code, drug name, production lot number, average piece weight, and actual count.

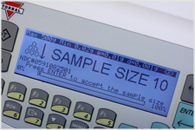

After the vial is tared and the drug has been scanned, the scale will search the database. If the drug is not found, the scale will ask you to select a sample size. Then simply make your selection, pour the sample into the vial, and press Enter to save the drug’s information. You can then proceed with the remainder of your count.

After the vial is tared and the drug has been scanned, the scale will search the database. If the drug is not found, the scale will ask you to select a sample size. Then simply make your selection, pour the sample into the vial, and press Enter to save the drug’s information. You can then proceed with the remainder of your count.

Maintaining the database and updating the average piece weight is also very easy. The scale’s “data entry reminder” feature will actually remind you to update the average piece weight. Let’s illustrate this very valuable feature: After taring the vial and scanning the NDC barcode, the scale will check to see when the last update was performed. If more than thirty days has passed, a reminder is displayed. You can then update the drug’s information as part of your counting process or ask the scale to remind you later. Depending on your application, the reminder can be set for thirty, sixty, or ninety days. Average piece weight can also be updated anytime with the use of the Sigma key.

| Are Pill Counters Contaminated? |

It's a question that no customer at your pharmacy will probably ever ask. It's true. When your customers come in to get a prescription filled, some of them are placing their lives in your hands. All of them are placing their health in your hands. You won't find any of them asking your pharmacy technicians if your pill counters are contaminated because the fact is, they're just not thinking about it. Contamination isn't for pharmacies, at least not in the eyes of your customers. Contamination is something that happens to meat that's not handled the proper way, or produce that comes into contact with salmonella. In fact, the Canadian news website, The Globe and Mail recently published an article that discussed the recall of Halloween candy this year. It was discovered that the individually-wrapped chocolate Kisses contained metal fragments, so the article served as a warning to customers as well as retail outlets. |

| Read more... |